Against the backdrop of global "dual carbon" goals and the full implementation of Extended Producer Responsibility (EPR) policies, TPU (Thermoplastic Polyurethane)—a critical material in footwear, automotive interiors, and electronic coating sectors—has seen its recycling and pelletizing demand surge at an annual rate of 22.3% (predicted by BloombergNEF). Traditional TPU recycling struggles to meet high-end market requirements due to performance degradation and complex processes. However, three frontier technologies—molecular-level chemical recycling, intelligent physical sorting, and high-performance modification integration—are comprehensively reshaping the TPU recycling and pelletizing industry landscape. As a professional manufacturer with over 10 years of experience in plastic recycling equipment, Weiquan Machinery translates these cutting-edge technologies into actionable production solutions through customized equipment R&D and full-chain service capabilities, helping global customers achieve the profit goal of "converting waste into high-value pellets."

I. Cutting-Edge TPU Recycling & Pelletizing Technologies: Breaking Through Performance and Efficiency Bottlenecks

Today, TPU recycling and pelletizing have evolved from "simple melt pelletizing" to a new stage of "precision recycling + performance enhancement." Three core technologies have become the key to industry competition:

1. Chemical Molecular-Level Recycling: Unlocking the "Performance Code" for High-End Applications

Chemical recycling decomposes TPU waste into monomers such as polyols and amines through alcoholysis, hydrolysis, and other processes, then resynthesizes high-purity TPU pellets. It is the only technical path that can achieve "recycled materials matching the performance of virgin materials." Its core breakthroughs lie in improved reaction efficiency and energy consumption control:

Microwave-Assisted Alcoholysis Technology: As adopted by Shenzhen Lvsu Technology, it achieves a one-pass TPU conversion rate of 92.5% at 180℃ under normal pressure. Compared with traditional heating methods, energy consumption is reduced by 35%, the tensile strength of recycled materials reaches over 95% of virgin materials, and the elongation at break stabilizes at 85%~92%. It has passed GRS certification and entered the electronic coating material supply chains of Huawei and OPPO.

Low-Temperature Depolymerization Process: Independently developed by Wanhua Chemical, this technology lowers the reaction temperature to 160℃. Special catalysts reduce molecular chain breakage, the VOC emission of recycled materials is less than 50μg/g (meeting the automotive interior standards of Volkswagen and BYD), and the daily output of a single production line is increased to 12 tons.

Addressing the needs of chemical recycling and pelletizing, Weiquan Machinery has custom-developed an integrated TPU depolymerization-pelletizing linkage line: equipped with an AI temperature control system for special reactors (real-time temperature adjustment ±1℃), an online viscosity monitoring module, and a closed-loop monomer purification device. This ensures the depolymerization reaction time is shortened to less than 2.5 hours while meeting CE and ISO certification standards. Currently, this production line has been exported to Germany, Southeast Asia, and other regions, serving TPU recycling projects supporting automotive OEMs.

2. Intelligent Physical Sorting: Laying the Foundation for High-Purity Recycled Materials

High-purity raw materials are the premise of high-quality TPU recycling. Traditional manual sorting is inefficient and error-prone, while intelligent physical sorting technology achieves precise separation of TPU waste from impurities through multi-dimensional identification and classification:

Near-Infrared (NIR) + AI Image Recognition Sorting: This technology integrates NIR spectral analysis and AI visual algorithms to identify TPU materials with different melting points, colors, and impurity contents at a sorting speed of 600 pieces per minute. The impurity removal rate exceeds 99.2%, effectively separating TPU from mixed plastics such as PVC and PE.

Electrostatic Separation for Micro-Impurities: Targeting tiny metal particles and inorganic contaminants in TPU waste, electrostatic separation technology uses differences in electrical conductivity to remove impurities as small as 0.1mm, ensuring the purity of recycled materials meets food contact and electronic grade standards.

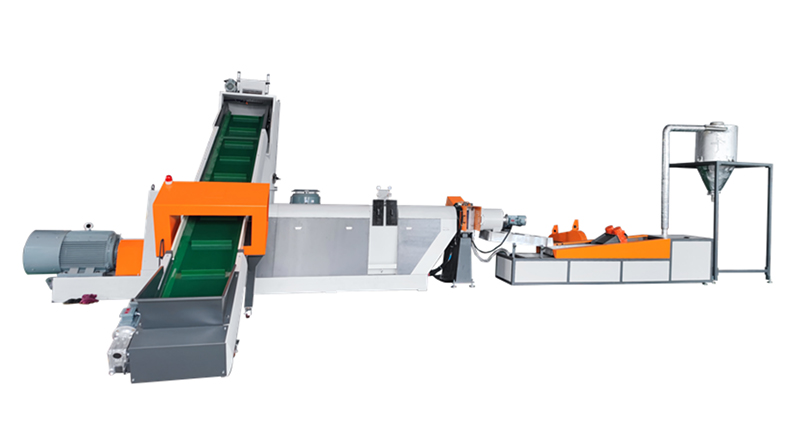

Weiquan Machinery’s TPU physical recycling line is equipped with a customized intelligent sorting module that can be adjusted according to the type of TPU waste (such as post-industrial scrap, post-consumer footwear waste, or electronic coating leftovers). The line integrates crushing, washing, drying, and sorting processes into one, reducing intermediate transportation links and improving production efficiency by 40% compared with traditional discrete equipment. With its stable performance, the line has been widely used in recycling projects in Europe and North America.

3. Integration of High-Performance Modification: Enhancing the Added Value of Recycled Pellets

To expand the application scope of recycled TPU pellets, high-performance modification technology has become a key link in the industry. By adding functional additives and optimizing the extrusion process, the performance of recycled materials is enhanced or upgraded:

Reinforcement and Toughening Modification: Adding nano-calcium carbonate or elastomer modifiers to recycled TPU improves its wear resistance and impact resistance. The modified recycled pellets can be used in automotive door panels and shoe sole materials, with performance reaching 90% of virgin materials.

Flame Retardant and Antioxidant Modification: Through the addition of environmentally friendly flame retardants and antioxidant masterbatches, the recycled TPU meets the UL94 V-0 flame retardant standard and has a service life extended by 3~5 years, making it suitable for electronic device casings and wire and cable sheaths.

Weiquan Machinery’s TPU recycling and pelletizing line is designed with a modular modification unit that allows customers to flexibly configure additive feeding systems according to product requirements. The line is matched with a twin-screw extruder with precise temperature control and uniform mixing, ensuring the modified recycled pellets have stable performance and consistent quality. It has obtained relevant international certifications and is trusted by customers in high-end application fields.

II. Why Weiquan Machinery Is the Trusted Partner for TPU Recycling Projects

In the fiercely competitive TPU recycling equipment market, Weiquan Machinery stands out with its professional strength and customer-centric services, becoming the preferred partner for global customers:

1. Over a Decade of Professional Experience in Plastic Recycling

Founded in 2010, Weiquan Machinery has accumulated more than 10 years of experience in the plastic recycling equipment industry. With in-depth insights into the characteristics of TPU materials and recycling processes, the company can provide targeted equipment solutions and avoid common technical pitfalls in production.

2. Customized Services Tailored to Customer Needs

Every TPU recycling project has unique requirements for raw materials, output, and product standards. Weiquan Machinery offers one-stop customized services: from pre-sales technical consultation and profit-cost analysis to customized equipment design and production, it fully meets the individual needs of customers. Whether it is small-batch laboratory equipment or large-scale industrial production lines, the company can provide suitable solutions.

3. Global Market Layout and Certified Quality

Weiquan Machinery’s products are exported to more than 50 countries and regions around the world, including Europe, North America, Southeast Asia, and South America. All TPU recycling and pelletizing lines have obtained CE and ISO certifications, complying with international environmental protection and safety standards, and ensuring smooth market access for customers’ products.

4. Comprehensive Pre-Sales and After-Sales Support

Weiquan Machinery adheres to the service concept of "customer success is our success." The professional team provides customers with detailed business plans, on-site installation guidance, operator training, and 24/7 after-sales technical support. Even in remote regions, the company can quickly respond to customer needs and ensure the stable operation of equipment.

III. Seize the 2025 TPU Recycling Opportunity with Weiquan Machinery

As the global demand for sustainable materials continues to grow, the TPU recycling and pelletizing industry is ushering in a golden development period. The application of frontier technologies is accelerating the transformation of the industry from "low-value recycling" to "high-value regeneration." Weiquan Machinery, with its advanced equipment, professional experience, and full-chain services, is committed to helping more enterprises enter the TPU recycling track and achieve environmental and economic benefits.

Whether you are planning to build a new TPU recycling factory or upgrade existing equipment, Weiquan Machinery can provide you with customized, efficient, and profitable solutions. Join us in the journey of "transforming waste into wealth" and jointly promote the development of the circular economy.

Contact Weiquan Machinery today to explore the latest TPU recycling and pelletizing technologies and start your sustainable development journey!

Keywords: TPU recycling machine, TPU pelletizing line, chemical recycling equipment, intelligent plastic recycling, high-performance modified TPU, CE certified recycling machinery, ISO approved TPU recycling line, 2025 TPU recycling trends, Weiquan Machinery

Post time: Dec-19-2025